New Products

PLCs

Window CE PLCs

PLC Trainers

Serial Modules

Operator Panels

Control and Monitoring thru Excel

SCADAs

Voice ModulePower Supplies

Relays

Position Transducers

RS232/Ethernet Converter

Wireless Modem

Power monitoring

Protection Devices

MarqueesVariable Frequency Drives

Industrial Computer

Encoders

Application Proyects

Combos

Tech Support

DownloadsWho are we?

Our customers

How to order

Home

Contact Us

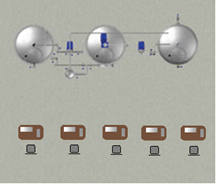

This mini-plant is one of the first real processes.It was developed to provide training , with a better and practical approach to the automation or control of industrial processses, for all type of disciplines such us: electrical, electronics, mechanics, mechatronics, control, automation, industrial, chemical, food and beverages, enviromental and production.

You can make lab practices on feedback, PID, multivariable and robust control. Several techniques such as classical, modern, and advanced control can be applied. All of them in real context. For technical, engineering, master or doctorate studies.

This system is both: educational and real. The whole process is instrumented according to your needs to produce small batches of Malta, Beer or Soda.

Fundamentals on the Process

The malt as raw material is ground and then mixed with water in the first tank. A temperature profile is applied to the resultant product to generate different properties on the enzymatic activation. The second stage is boiling and the second tank is used at some part of the process where you add the hops. All the liquid is stirred. After some specific time the product must be cooled using the plate heat exchanger. The final product is stored for fermentation when yeast is added.

When the product is fermented you can drink it as beer, add water and sweet solution to dilute it on Malta or without the heating and fermenting to produce Soda.

- The modules include several sensors and sensing technologies, all of them accessible trough special connectors.

- The educational plant is a fully open technology so you can connect it to any control system or PLC no matter the brand

- Level Control: discrete and continuous sensing with and without contact.

- Flow Control: With usage of proportional valves.

- Pressure Control: re-circulating systems and pump control.

- Temperature Control: For high (heating) and low (Cooling) temperature.

- PH Control: In-line measurement of process signals.

- Assembly, construction and design in stainless Steel under sanitary specifications.

- All the system for sensing, control, refrigeration and monitoring.

- The students learn gradually all the process parameters until they can prepare a REAL production batch and then TASTE their own product.

- Enhancement of student’s creativity and learning trough the real control or our mini-process.

- Empower your students with entrepreneurship.

- The different groups of students can work simultaneously designing their own control algorithms.

- Safety system to protect persons and equipment.

- Work with small batches.

In this kind of plant a control panel allows you to manage all the involved processes or intervention of the whole operation. Through a touch screen interface you can make manual or automatic operation of the whole process, observe the variable during the production cycle, diagnose or stop the production process.

A pilot plant is offered to those research or educational professionals who prefer to focus on the process rather than the individual knowledge of every device or control technique used . A very easy, safe and reliable operation is guaranteed.

The plant is designed not like an integrated process, but like a group of separate sub-processes which can be individually operated. All the signals coming from sensors and actuators are connected to different panels where the students can make connections to our PTS F1616 or any other control device or PLC.

On every work-station, a group of students can develop their own control algorithms, with either manual, remote, Stand alone or PC control. Operation can be achieved.

This is a very powerful tool for courses on control, automation, mechatronics and electronics.

One of the big advantages is that every workstation doesn’t affect the others. This consideration is useful to simultaneously attend several students. At the end of the course, the entire group can be coordinated to make a complete production run.

- Other Products

- Climate change Fitotron.

- Algae Biofuel Pilot Plant.

- Bioethanol Plant.

- Inverted Pendulum.

- Speed, position and generation plant.

- PLC trainer (Generic, AB, Siemens, e.t.c.).

- Solar heating system.

- Hydrogen cells trainer.

- Solar and Eolic energy trainer.

- Water supply plant.

- Motor-generator plant.

- Drives.

- SCADA.

- Other didactic process (in preparation)

- Motor-generador.

- Drives

LATIN TECH INC.

PH: 305 848 3517

8004 NW 154 ST. # 621

Miami Lakes, FL 33016, USA

Discover and new experience in education and research.

More realistic lab practices

For aditional information please CONTACT US

© LATIN TECH 2005