1) Ethernet Port

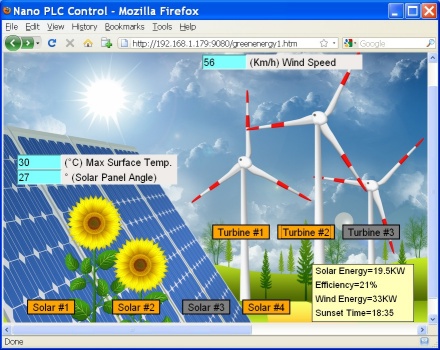

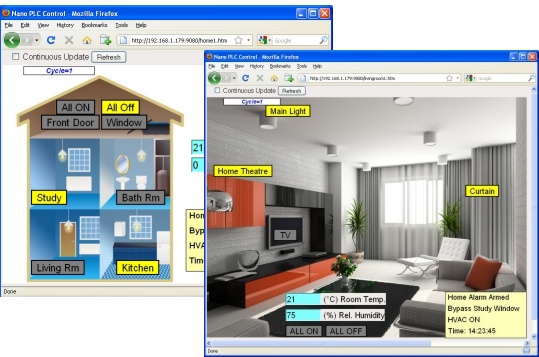

Have you ever asked for the price of a PLC or PLC trainer with Ethernet port? It’s almost the price our complete PLC trainer PTS F1616. You can access your equipment from anywhere in the world!

2) Analog I/O

8 Analog input channels (0-5V) and 2 Analog output channels( 0-5V) or 0-10V (Software selectable!). Expandable to 4 channels (0-5V) with 12 bits of resolution.

3) Communication ports

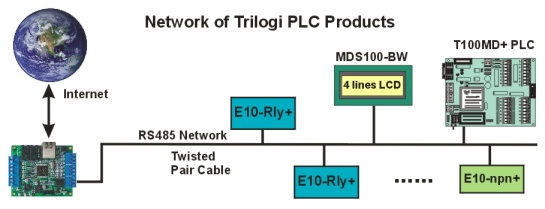

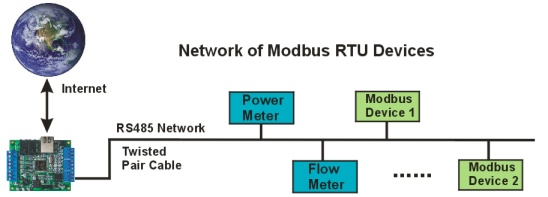

Ethernet, RS 232, and two RS 485 ports.

Event-driven Emailing. Create and save data file on a networked PC's hard disk. TCP connection to any Server IP address:port number (e.g. to NIST Timer Server).Extremely easy Peer-to-peer (or machine-to-machine) PLC communication. Support both Modbus/TCP Server (5 simult. connections ) and Modbus/TCP Client.Direct connection to LAN or Internet for programming, monitoring and Remote Control

Serial port supported protocols: MODBUS RTU, MODBUS ASCII, OMRON C20H Host Link Commands

Default COM speed 38,400 bps, may be set from 1200 to 115.2K & 230.4K bps.

4) Two lines x 16 characters LCD to easily display application or control data.

6) Power Supply included. You only need to plug it to any AC outlet and start working.

7) Multi-function Digital Outputs.

The PLC trainer has 16 outputs available on side connectors. Outputs 1-4 and 9-10 are relay outputs with 5 amps capacity. Outputs 5-8 can be used as normal DC outputs (npn type), PWM outputs or like Light dimmer control changing the firing angle of external TRIACS or SCRs. The outputs can also drive directly either one unipolar stepper motor (4 motor wires) or a two stepper motor drives( pulse and direction). Ideal for motion control.

9) Multi-Function Digital Inputs.

The PLC trainer has 16 inputs (NPN or PNP)available on the bottom connector. The first two are assigned to two push buttons and 4 switches for you to perform digital inputs simulations. Inputs 1 -6 are High speed inputs that you can use to connect quadrature encoders . Inputs 7-16 are normal digital inputs.

10) Battery Back Real Time Clock

Real Time Clock and Calendar (Year, Day, Month, Hours, Min, Sec, day-of-week)

- Lithium CR1632 battery-backed (runs up to 5 years without ext.l power or 10 years if powered off only 1/2 of the time)

- Real Time Clock can be updated with Atomic clock data from NIST time server if PLC is connected to the Internet

11) Infra Red Remote Sensor which works at 32KHz (Send and Receive commands)

12) XBEE socket solder pad to enable the PLC to connect to ZIGBEE wireless sensors and control modules.

13) LEDs for all 3 serial ports 14) Potentiometer with knob and precision power supply to be used to setup analog value or as a very easy tool to test control programs using analog variables. |